APS CEO Chau Wing Chon: Rapid Commercialization of SiC Power Electronics - A new Era

On November 8-10, 2023, the Fourth Asia-Pacific Conference on Silicon Carbide and Related Materials (APCSCRM) was successfully held at the Palace Garden Hotel & Resorts in Beijing, China, attracting more than 800 domestic and foreign experts, scholars, and business representatives, as well as nearly 400 active participations from enterprises.

APCSCRM invited more than 50 renowned experts, scholars, business leaders, and capital institutions around the world to share the latest research progress of global wide bandgap semiconductor technologies, exchange forward-looking views of the industry, showcase the advanced achievements of enterprises, and promote connection within the industry.

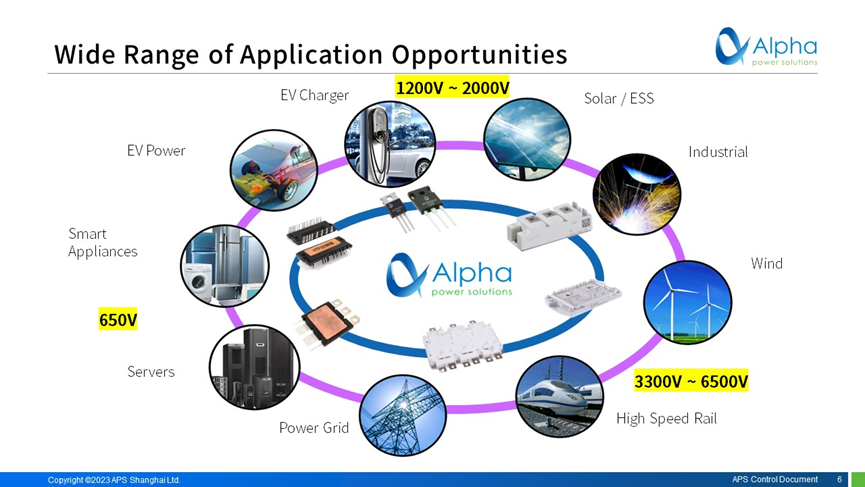

APS CEO Chau Wing Chon was invited to participate in a speech with the theme of "Rapid Commercialization of SiC Power Electronics - A new Era", to share the current development of the SiC market, the broad devolopment prospects for silicon carbide devices provided by medium and high voltage applications, and look forward to the future of SiC MOSFET.

Mr. Chau Wing Chon first said in his speech that according to Yole Intelligence " Power SiC 2023 Annual Market Report", the silicon carbide market revenue is expected to grow from $1.7 billion to $9 billion at a compound annual growth rate of 35%. Popular areas such as new energy vehicles, DC charging module, photovoltaic energy storage, smart home appliances, satellite communications, high-voltage power transmission and transformation, and rail transit are driving the growth of power SiC devices, of which automotive and industrial applications are the main drivers of SiC market growth. SiC devices have become ideal devices in new energy vehicle devices due to their excellent characteristics. SiC devices offer better switching performance, lower losses, and allow for higher operating junction temperatures, which in turn enables higher power density, reliability, and efficiency.

In the first half of 2023, the overall penetration rate of new energy vehicles is close to 30%, compared with 5.9% in 2020, a five-fold increase in just three years! At present, most of the batteries and power conversion systems in new energy vehicles on the market use 400V voltage architecture, but when the mileage exceeds 500km, new energy vehicles should use 800V voltage architecture to achieve shorter charging time and higher efficiency.

The mainstream trend is for new energy vehicles to move from 400V to 800V voltage architecture. High-power fast charging has become the industry consensus to meet the needs of fast charging and energy saving. By 2027, the share of 800V voltage platforms will increase from 4% today to 45%.

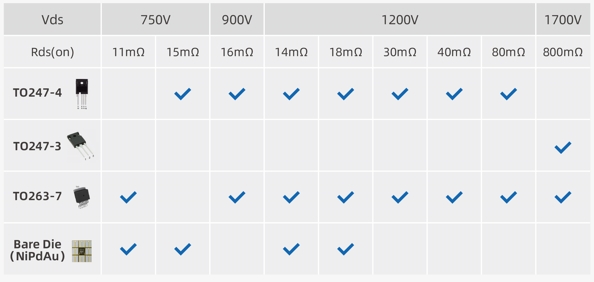

To meet market demands, APS has actively laid out and developed in the automotive market this year. APS has already mass-produced automotive-grade silicon carbide MOSFET, such as 1200V 35/70/160mΩ and 650V 30/45/60mΩ, using TO247-4 and TO263-7 package forms. These products have high reliability and robustness, as well as excellent switching and conduction performance. In addition, they have outstanding body diode reverse recovery characteristics, which can significantly reduce system costs for on-board chargers (OBC) and DC-DC applications. All products have passed automotive AEC-Q101 reliability verification and 960V high-voltage H3TRB harsh testing.

Mr. Chau Wing Chon also mentioned that although China's silicon carbide technology started late, the whole industrial chain is striving to catch up. In the field of EPI, the quality of silicon carbide EPI products produced by leading domestic manufacturers is comparable to that of international large factories, and it is expected that by the end of 2023, the total production capacity of China's 6-inch silicon carbide EPI may exceed 1 million pieces, providing silicon carbide EPI products for the global market.

As silicon carbide substrate is one of the core links of the industrial chain, domestic substrate companies are developing rapidly. At present, China has a large number of domestic 6-inch silicon carbide substrate manufacturing diodes. In the field of MOSFET, many manufacturers have also begun to use domestic 6-inch substrate. According to Trendforce, China's 6-inch SiC substrate production capacity may only account for 5% of global capacity in 2023, but by 2024, China's total production capacity may grow to 50%, reaching 1.5 million pieces. In contrast, the capacity expansion attitude of international 6-inch SiC substrate manufacturers is more conservative while Chinese manufacturers have an optimistic attitude and are eager to expand their market share.

Compared with the 6-inch wafers, it is expected that the price of 8-inch SiC EPI wafers will soon decline as the 6-inch technology gradually matures. The iteration time to 8-inch wafers will become shorter, and a large amount of 8-inch wafer production capacity will be released. Using the same technology for 8-inch wafers can save up to 35% of the cost. However, 8-inch wafers still have some technolological challenges that require more effort in terms of equipment and process control.

According to inSemi, international substrate manufacturers will start production of 8-inch substrates in 2023-2024, while domestic manufacturers will start production in 2025-2026. China is catching up and closing the gap with international manufacturers!

In the field of silicon carbide diodes, the technological skill of domestic manufacturers has reached the level of foreign manufacturers. Around 2013, domestic SiC diode manufacturers began to use 4-inch technology, and APS took the lead in successfully using 6-inch technology in 2015 to achieve a breakthrough of domestic technology in this field. As domestic diode technology matures, more and more local manufacturers have entered the market, which has taken market share from IDM companies.

In the field of silicon carbide MOSFETs, there are currently more than 40 local IDMs and SiC design companies in the market. In 2020, only a small number of SiC manufacturers could provide samples, while APS was mass producing in 2021. By 2022, more companies entered the MOSFET market. Although domestic technology is catching up fast, there is still a generation gap with IDMs. Planar MOSFETs are still the mainstream of future generations of products. When Rsdon,sp is lower than 2.0, planar MOSFETs may reach their limits, requiring new technologies and structures.

APS also successfully launched the third-generation silicon carbide MOSFET this year, which includes various mainstream specifications in the market, such as 1200V 14/18/30/40/80mΩ and 750V 11/15mΩ. Compared with the previous generation, the third-generation silicon carbide MOSFET has undergone further improvements in its technology, craftsmanship, and product structure. The product has better parameter consistency, lower switching losses, and superior conduction characteristics to meet the application requirements of high reliability and high-performance. It is widely used in DC charging module, photovoltaic & energy storage, OBC/DCDC/main drive, and other fields.

Finally, Mr. Chau Wing Chon said that China's silicon carbide market is ushering in vigorous development. Although there is still a gap between China's SiC technology and international manufacturers, we are trying to catch up. Domestic manufacturers are actively planning, and in the future it is expected that through in-depth collaboration between upstream and downstream of the industrial chain, domestic silicon carbide devises will gradually be used as replacements in various application fields.

*This Presentation is intended for general information purposes only and should not be relied upon for any business and