Product Marketing Director Heming Li :Application and Prospects of Domestic SiC devices in the New Energy Market

The 2023 New Energy Power Semiconductor Industry Chain Innovation Summit was successfully held in Shanghai from December 21 to 22. As a leading third-generation semiconductor supplier in China, APS was invited to attend the conference, and Product Marketing Director Li Heming shared a speech on the application and prospects of domestic silicon carbide devices in the new energy market with the attendees.

In his speech, Mr. Li Heming first introduced the explosive growth period of the silicon carbide industry. As of 2022, data shows that the global silicon carbide market size is around 1.7 billion US dollars and is expected to reach 9 billion US dollars by 2028. The growth of the silicon carbide market size mainly benefits from the vigorous development of new energy vehicles, and it is particularly exciting that new energy accounts for up to 80% of the entire market share. In the current uncertain environment, the market prospects for domestically produced silicon carbide are very promising.

The new energy vehicle industry in China is growing rapidly. Compared to 2021, the number of new energy vehicles has increased from 3.55 million to 6.88 million, with a growth rate of 93.4%. It is expected that by 2023, the number of new energy vehicles will continue to maintain a good momentum of growth, reaching 8-10 million units. Of particular note, with the transition of new energy vehicles from 400V to 800V voltage architecture, high-power fast charging has become an industry consensus. Most domestic OEMs have already launched or planned silicon carbide models, which will further expand the application scale of silicon carbide devices in the field of new energy vehicles.

Silicon carbide power devices play a core role in the power electronic drive system of new energy vehicles. Compared to traditional silicon-based power semiconductor devices, silicon carbide power devices have significant advantages in terms of voltage resistance, switching losses, and high temperature resistance. Therefore, the use of silicon carbide power devices helps to achieve lightweight and efficient power electronic drive systems for new energy vehicles, further promoting the development of automotive electrification.

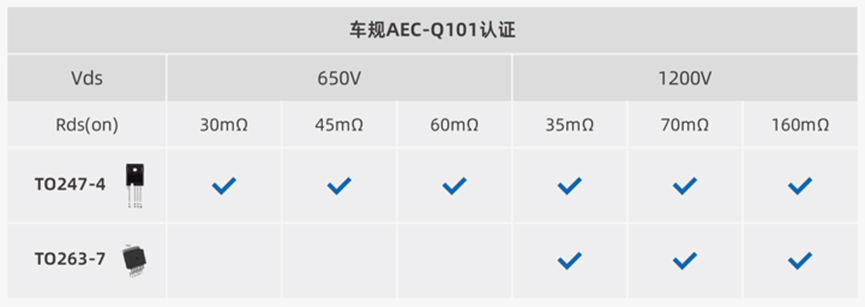

To meet market demand, APS has successfully launched multiple automotive grade silicon carbide products, covering mainstream market specifications such as 1200V 35/70/160mohm and 650V 30/45/60mohm, to meet the needs of different voltage applications. These products cover mainstream market specifications, such as 1200V 35/70/160mohm and 650V 30/45/60mohm, to meet the needs of different voltage applications. APS automotive grade silicon carbide products meet the reliability verification of automotive specification AEC-Q101 and have passed HV-H3TRB testing.

In terms of product structure, the second-generation automotive grade SiC MOSFET of APS continues the superior performance of the previous generation product. Through process optimization, the conduction resistance per unit wafer area is reduced, and the switching performance is further optimized. In addition, Kelvin Source packaging is also adopted to avoid the sharing of source circuits between the driving circuit and the power circuit. The switching speed and anti-interference ability of the device have been significantly improved, providing more possibilities for increasing switching frequency and improving system efficiency and power density.

The scale of silicon carbide devices in the new energy market is constantly expanding, especially in the photovoltaic industry, which has attracted much attention. According to different power requirements, silicon carbide devices can be applied in various scenarios such as interoperability, commercial, and power plants. For the entire photovoltaic energy storage system, silicon-based solutions are more suitable for complementary scenarios such as small industries when the power is below 10kW. However, in power demands ranging from 10kW to 300kW, and even above 300kW, due to the influence of some catalytic factors, the application scenarios of silicon carbide devices are becoming increasingly diverse. Firstly, due to the increase in power density, the demand for power device performance is also increasing, which provides an opportunity for silicon carbide devices to replace IGBTs. Secondly, energy storage systems require bidirectional power conversion, which places higher demands on the switching performance of devices, especially the recovery performance of diodes. Under this trend, the opportunities for silicon carbide have been further increased.

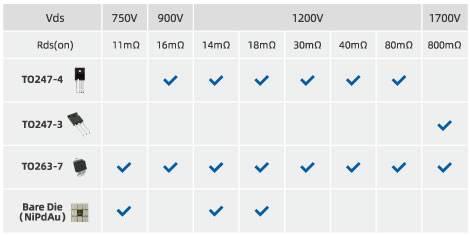

APS has also launched the third-generation silicon carbide MOSFET this year, such as 1200V 14/18/30/40/80m Ω and 750V 11m Ω. In terms of product structure, the third-generation silicon carbide MOSFET has undergone further technological and process improvements compared to the previous generation. The product has better parameter consistency, lower switching losses, and better conductivity characteristics to meet the requirements of high reliability and performance applications. It is widely used in charging piles, photovoltaic &energy storage, vehicle OBC/DCDC/main drive and other fields.

The continuous upgrading of domestically produced silicon carbide devices not only promotes the development of silicon carbide devices in the field of new energy, but also enhances China's technological strength and market competitiveness in this field. Through the widespread application of domestically produced silicon carbide devices, APS will continue to innovate and research and develop, which can better meet market demand, reduce energy loss, improve system efficiency, and promote the sustainable development of the new energy industry.