APS: Standing at the forefront of the silicon carbide trend, leading the development of power electronic devices

Silicon carbide is currently the most mature third-generation semiconductor material and has become an important technology for China's new era semiconductor to compete with the international market. It meets the modern industry's demands for high power, high voltage, and high frequency, greatly promoting China's leading position in the global market in application fields such as new energy vehicles, photovoltaic and wind power, smart grids, and 5G communications. As a leading third-generation semiconductor supplier in China, APS pursues the industrialization of leading semiconductor fields, enriches China's semiconductor ecosystem, and helps China's silicon carbide technology applications stay at the forefront of the world. On July 8, 2024, at the electronica Shanghai in the Electronic China interviewed Kathleen Fan, the sales VP of APS, and shared the company's technological progress and solutions in silicon carbide.

Challenges of Third-Generation Silicon Carbide Power Semiconductors

In recent years, China's silicon carbide industry has flourished, and the market size has continued to expand, but it faces multiple challenges. Kathleen pointed out that although SiC technology has obvious advantages over traditional silicon-based technologies, including higher energy efficiency, wider operating temperature range, and stronger durability, the commercialization process is still restricted by obstacles such as manufacturing complexity and cost control.

At the current forefront, the key for China's third-generation semiconductor industry to mature is to improve the yield and reduce costs to enhance the cost performance. Although the performance advantages of SiC MOSFET are significant, the production cost is relatively high. Especially, the yield on the expansion from 6-inch to 8-inch wafers still needs to be improved. Strategies such as adopting advanced processes to reduce the chip area and optimizing the process to improve the yield are dedicated to reducing costs and enhancing the cost performance of products.

Kathleen said that another challenge is that the reliability of silicon carbide devices needs to be improved. The production process and technology have not yet reached the maturity of silicon devices, and problems such as threshold voltage drift need to be solved urgently. At the same time, the scarcity of SiC materials leads to an imbalance between supply and demand, and the long supply chain verification cycle brings challenges in terms of time cost for new entrants. However, with the continuous expansion of the market size, the influx of capital and the continuous progress of technology, these challenges are gradually alleviated.

Regarding the breakthrough path for the challenges of silicon carbide devices, Kathleen pointed out that in the long term, the maturity of the SiC industry chain will rely on the synergy of the three forces of technological innovation, large-scale production, and supply chain optimization. It is worth noting that this process is not achieved overnight but requires the joint efforts of upstream and downstream enterprises in the industry, as well as multi-dimensional support from policies, markets, and technologies. "The ultimate goal is to build an efficient and sustainable SiC ecosystem to provide solid technical support for emerging fields such as clean energy and smart grids."

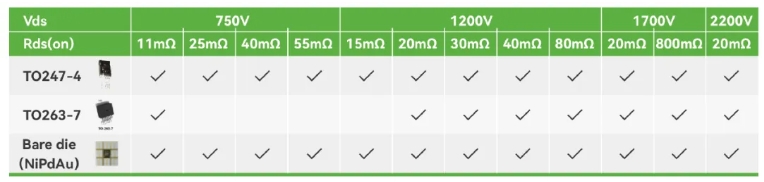

Although the rise of China's third-generation semiconductors is relatively short, the industry has developed rapidly, and the market's demand for high power density, high efficiency, and high reliability is increasing day by day. APS closely follows the market trend and actively adjusts its product strategy to meet the constantly changing needs of customers. It has already deployed 650V, 750V, 1200V in the high-voltage field and plans to launch 1700V and 2000V series products in the future. According to the 3-5-year long-term planning of benchmark customers, it responds quickly to market changes and develops and expands the product line.

Core competitiveness of APS

With the development of the third-generation semiconductor, APS has been deeply cultivating in the field of silicon carbide technology since its establishment and was the first to successfully apply 6-inch silicon carbide technology in China.

Firmly believing that investment in scientific research is the key for APS to maintain technological leadership and market competitiveness. Kathleen pointed out: "We continuously increase the intensity of R&D and have accumulated rich technology and experience. We are in a leading position in China in the design, R&D, and manufacturing process of SiC MOSFET. We have obtained more than 40 independently developed patents, and more than 60 patents are under application. These patent technologies provide strong technical support for our products."

It is particularly worth mentioning that APS has not only made significant achievements in planar SiC MOSFET but is also actively tackled the technical difficulties of trench MOSFET. "Trench MOSFET shows many advantages in design and performance compared to planar type, especially in high-voltage and high-frequency applications, which will bring more efficient and reliable solutions to our customers," Kathleen said.

In terms of chip manufacturing, as a power semiconductor company under HDSC, the cooperation between APS and GTA, the first domestic wafer foundry to mass-produce 6-inch SiC devices, enables APS to utilize its advanced manufacturing capabilities to achieve large-scale production and high-quality delivery of SiC devices. Since 2019, APS has achieved mass production of 650V and 1200V SiC diodes, and then batch shipments of SiC MOSFET in the fourth quarter of 2021, becoming the first domestic manufacturer to mainly produce and successfully ship a large number of 1200V SiC devices. The stable performance of APS's single-tube products in customer shipments is not only a reflection of the company's comprehensive strength but also ASP's unremitting pursuit of quality and service.

The rapid application of SiC MOSFET in emerging fields

Silicon carbide power devices are rapidly emerging in multiple fields such as new energy vehicles, photovoltaic energy storage, and motor drives with their outstanding performance. Kathleen said that the adoption of SiC technology can break through the performance limit of traditional silicon-based devices, significantly reduce conduction loss and switching loss, and can work stably in extreme environments such as high voltage, high power, high frequency, and high temperature.

Take new energy vehicles as an example. SiC devices can significantly improve the performance and efficiency of key components such as motor controllers, on-board chargers, DC/DC converters, and charging piles, effectively extending the vehicle's cruising range, shortening the charging time, and improving the utilization rate of battery capacity. Similarly, in charging piles and photovoltaic energy storage systems, SiC devices have also become the key to improving system energy efficiency and reducing costs due to their low loss and high efficiency characteristics.

For application fields such as charging piles, photovoltaic energy storage, and on-board OBC/DCDC/main drive, the third-generation SiC MOSFET product series launched by APS covers product specifications of 750V 11/25/40/55mΩ, and 1200V 15/20/30/40/80mΩ, etc., adopting TO247-4 and TO263-7 packaging forms. It shows better parameter consistency, lower switching loss, and better conduction characteristics to meet the requirements of high reliability and high performance.

The Innovative Application and Future Development Strategy of SiC MOSFET in Electric Vehicle Drive Systems

With the accelerated pace of global green energy transformation, the new energy vehicle market is experiencing unprecedented growth. Especially in the main drive inverter field, the technological innovation centered on SiC MOSFET is becoming a key force driving the industry towards the 800V high-voltage platform. The introduction of SiC MOSFET not only significantly improves the efficiency and power density of the electric drive system but also enables a faster charging process, meeting consumers' urgent needs for longer cruising range and shorter charging time.

In the 400V/800V main drive market, APS has established an industry-leading position with its comprehensive SiC product line and excellent verification experience. The company has successfully launched automotive-grade SiC products covering mainstream market specifications, including 1200V 35/70/160mohm and 650V 30/45/60mohm SiC MOSFET devices, meeting the diverse needs from low voltage to high voltage applications.

Centering on the customers' concerned demands and the strict indicators of industry standards, Kathleen said:” The automotive-grade SiC products of APS strictly follow the AEC-Q101 reliability standard and have passed the HV-H3TRB test, ensuring stable performance under extreme conditions. Facing the strict requirements for performance and reliability of high-voltage drive systems, APS, through careful design and process optimization, has found the best balance between performance and cost, ensuring that the products can seamlessly integrate into the actual working conditions of the main drive motor and providing solid technical support for the stable operation of the high-voltage drive system.”

Regarding the future development strategy, APS will continue to deeply cultivate technological innovation in SiC MOSFET, dedicated to developing silicon carbide power devices with higher performance and lower cost to meet the increasingly diverse demands of the new energy vehicle market. Kathleen disclosed, "The company plans to further expand the product line, covering a wider range of voltages and powers, and at the same time, strengthen cooperation with the world's top automotive power supply enterprises to accelerate the wide application of SiC technology in the field of new energy vehicles."

Kathleen firmly believes that through continuous technological research and development and market exploration, APS will lead the electric drive system of new energy vehicles into a new development stage and contribute more to global green travel. With the continuous maturity and popularization of SiC MOSFET technology, a more efficient and environmentally friendly future travel era is accelerating.

Interviewee: Kathleen Fan, VP of Sales at APS

Kathleen, the current Vice President of Sales of APS, with her rich industry experience and outstanding leadership skills, demonstrates profound accumulation and unique insight in the semiconductor field, especially in the automotive electronics market. Kathleen previously worked at Micron Technology and ON Semiconductor as a key account manager. During her tenure at ON Semiconductor, she led the completion of a landmark strategic cooperation of silicon carbide modules in the main drive project of strategic automotive customers, making a significant contribution to promoting the silicon carbide module business of ON Semiconductor in the Asia-Pacific region. Subsequently, she joined Longsys Electronics and held the position of Director of the Automotive China Market. During her time at Longsys, with her acute market insight and outstanding business expansion ability, she successfully expanded the company's market in the automotive electronics field. She accurately grasped the unique pulse of the Chinese automotive market, deeply participated in and led the implementation and landing of a series of key projects, making important contributions to the increase in market share and brand influence of Longsys Electronics in the automotive industry.